This innovative system, called the “conveyor road”, is designed to solve several problems at the same time: the lack of truck drivers, the growing demand for goods deliveries and the need to reduce carbon dioxide emissions.

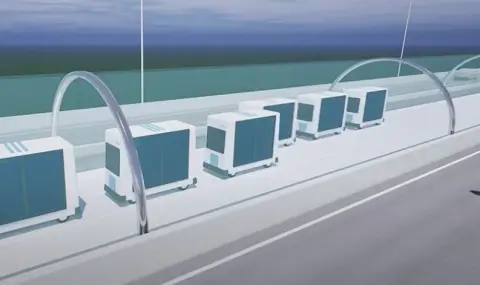

According to the plan of the developers, large containers on wheels will move on special road lanes without drivers. The system will be fully automated and will be able to operate around the clock. The launch of test trials is planned for 2027, and full operation - for the mid-2030s.

The problem with the shortage of truck drivers is relevant not only for Japan. A similar situation is observed in many countries around the world, caused by a number of factors, including the aging of the population and the low attractiveness of the profession of a professional driver.

The Japanese project can serve as an example for other countries facing similar problems. Similar initiatives are already being discussed in Switzerland and Great Britain. Despite the obvious advantages, the implementation of such a large-scale project is associated with a number of difficulties.

It is necessary to solve the problems of financing, security, interaction with the existing transport infrastructure and many others. However, if the project is successful, it could revolutionize the field of freight transport and open up new opportunities for the development of the economy and logistics.

Experts note that the automation of freight transport is not only a technical, but also a social task. It is necessary to take into account the interests of all participants in the process: drivers, logistics companies, manufacturers and consumers.

In addition, it is important to develop clear rules and standards for the safe operation of automated transport systems. The Japanese project to create an automated cargo system is ambitious and innovative. Its implementation can be an important step towards creating a more efficient and sustainable transport system. See also the video on the subject.