A Bulgarian team called ElectRU from the University of Ruse once again demonstrated its engineering abilities and made us proud to be Bulgarians. The specialists presented a new electric vehicle, called in the Danube city "the Ruse Tesla", participating with it in the Shell Eco-marathon Europe and Africa 2025.

This is a very innovative prototype of a city car, which is an example of innovations in the field of energy efficiency and sustainable production. This year's participation was marked by a completely new concept, the result of a year of hard work, including practically round-the-clock efforts in recent months.

Construction and materials: Minimum weight, maximum strength

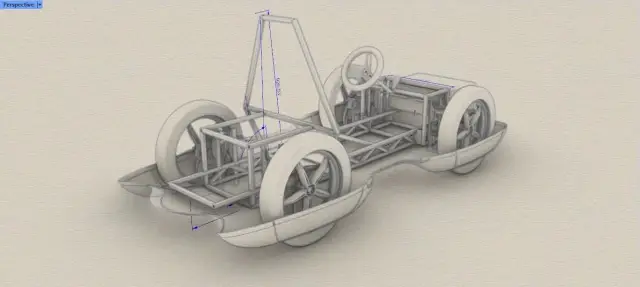

One of the main focuses of the new prototype is achieving a minimum weight for the car's class, without compromising on safety and reliability, which is a key requirement of the organizers. To achieve this, the team has relied on a combination of cutting-edge materials and production technologies:

Carbon fiber body: The use of carbon fiber for the body provides exceptional strength at low weight. For the first time, technologies with an extremely low carbon footprint and environmentally friendly materials have been applied in the production of the body, emphasizing the team's commitment to sustainable development.

Chassis and suspension made of ultra-light metal alloys: These materials further contribute to reducing the total weight of the car, which is only 95 kg.

Production innovations: Robotics and additive technologies

To minimize waste, increase accuracy, and speed up the production process, the team has integrated high-tech methods:

Robotic milling system (KUKA robot): This system, acquired under the "Rousse Research University" project and installed in the university's "Scientific and Research Complex", plays a key role in the production of the body. It provides exceptional precision and enables the production of parts that would be impossible using conventional methods.

Additive technologies (3D printers): The use of 3D printers for the overall production further reduces production time and increases the possibilities for creating complex and optimized parts.

Drive and electronics: Engineering by ElectRU

In accordance with the rules of the category, the electronics and control software are entirely developed by the team, specifically for the needs of the competition.

Brushless electric motor: The car is powered by a brushless electric motor with a peak power of 2 kW, which ensures efficient and reliable movement.

Specialized controller: The motor is controlled by a specially designed controller, ensuring optimal performance.

LiON battery: Power is provided by a LiON battery with 14 cells and a capacity of 0.8 kW/h, balancing between energy density and weight.

Technical parameters and functionality

The ElectRU prototype not only meets the efficiency requirements, but also includes systems necessary for operation in urban conditions:

Dimensions: Length of 3.00 m, height of 1.20 m and width of 1.19 m, optimized for urban environments.

Maximum speed: Up to 60 km/h, which is adequate for urban traffic and racing conditions.

Hydraulic braking system: For safety and reliability, the car has a hydraulic braking system made up of 2 circuits, each with an independent brake pump, ensuring high braking efficiency.

Urban functionality: All necessary systems for urban conditions, such as lights, sound signal, wipers and others, are integrated, making it ready for potential future integration in a real environment.

With this prototype, the ElectRU team is not just participating in a competition, but is demonstrating the high achievements of Bulgarian engineering education and the capacity to create innovative and sustainable transport solutions, which our country definitely has.