Chinese company Hantek has achieved a real breakthrough, introducing the world's first all-aluminum low-pressure die-cast car frame designed for a large-scale SUV. This engineering masterpiece is embedded in the heart of the flagship electric beast - BYD Yangwang U8L, whose official debut is expected in the fall of 2025. The innovation was presented with fanfare on December 2 at the Industrial and Technological Innovation Conference in Hubei Province, highlighting its strategic importance for China's industrial sector.

Hantek engineers have not just expanded, but literally destroyed the boundaries of traditional manufacturing methods for large-scale thin-walled structures. The frame designed for the Yangwang U8L boasts a colossal 4.2 square meters of projection area and an impressive range of wall thicknesses – from just 4 mm to an impressive 50 mm. This ratio of over 12:1 was previously considered an unattainable mission in industrial casting. The reason? The extremely difficult task of controlling the different crystallization rates of the metal in parts with such drastically varying thicknesses. According to Hantek, no other manufacturer in the world has ever successfully cast such a complex, massive and extreme frame.

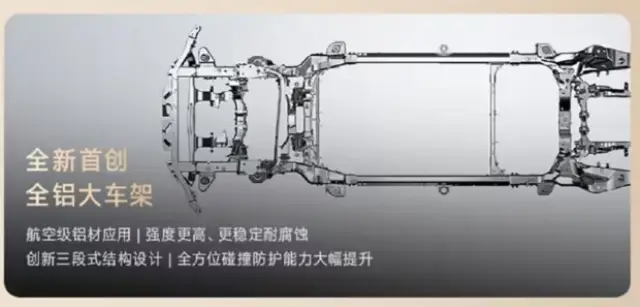

Traditional aluminum chassis, as we know them from SUVs and pickups, are a conglomerate of dozens of components that are joined together by welding, riveting or pressing. Each of these joints is a potential Achilles heel in the structure, complicates manufacturing and, more importantly, reduces overall rigidity. Hantek's one-piece forged solution elegantly eliminates all of these problems. The integrated, jointless structure provides a dramatic increase in torsional rigidity, uniform distribution of impact loads and overall structural integrity. The company emphasizes that the specially developed aluminum alloy and advanced heat treatment guarantee an optimal balance between high strength, impact elasticity and long-term durability.

This innovative frame finds its rightful place in the BYD Yangwang U8L - an ultra-luxury full-size electric SUV, the price of which starts at 1.28 million yuan. This is a car that literally explodes the notions of power and luxury. Based on the innovative e4 (Yisifang) platform, the U8L combines a 2.0-liter turbocharged engine with four independent electric motors and a Blade battery with a capacity of 55.53 kWh. The total output of this power symphony reaches 880 kW (1,180 hp), and the maximum torque hits a respectable 1,520 Nm. With an electric range of 200 km and a total range of up to 1,160 km, and with support for 13 different driving modes, this is heavy artillery. The car is also equipped with the ultra-modern driver assistance system “God's Eye“, which relies on lidar, radar and infrared sensors.

The interior of the Yangwang U8L is a journey into the world of high luxury. It offers six individual seats, a second row in business class, multiple high-tech screens, a panoramic roof, a built-in refrigerator, a Naim audio system with 32 speakers and 14 airbags. The noise level in the cabin is incredibly low – only 64.6 dB at a speed of 120 km/h.

During the conference, representatives of the Yangtze River Industry Group explicitly emphasized that Hantek's low-pressure casting technology is not just an achievement of one company, but a critical step forward for the entire Chinese engineering industry. It could change the paradigm in creating large vehicle frames in the future, allowing manufacturers to abandon cumbersome multi-component structures. With partnerships already in place with key Chinese giants such as BYD, Nio, FAW Hongqi and Dongfeng Lantu, we can reasonably expect that this futuristic technology will soon enter other models, setting a new gold standard in automotive engineering.