BMW is entering the final phase of preparations for the series production of its third-generation hydrogen power unit. This is expected to happen in 2028 and open a new chapter in the company's strategy for “technological openness“.

The new engine will be assembled in Munich, Steyr and Landsgut, which are well-known BMW centers. This move reinforces the company's commitment to the development of the European innovation infrastructure and to zero emissions.

Partnership with Toyota and revolutionary efficiency

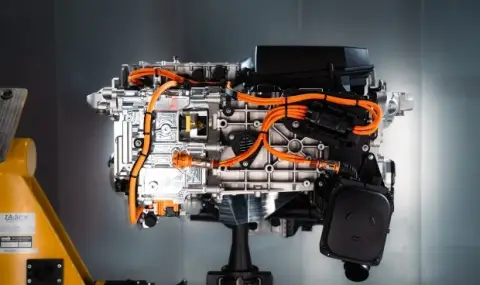

The development of the hydrogen unit is in close cooperation with Toyota Motor Corporation. While Toyota supplies the individual fuel cells, BMW engineers in Munich are fully responsible for the overall system architecture. This partnership allows both companies to combine their expertise and optimize costs.

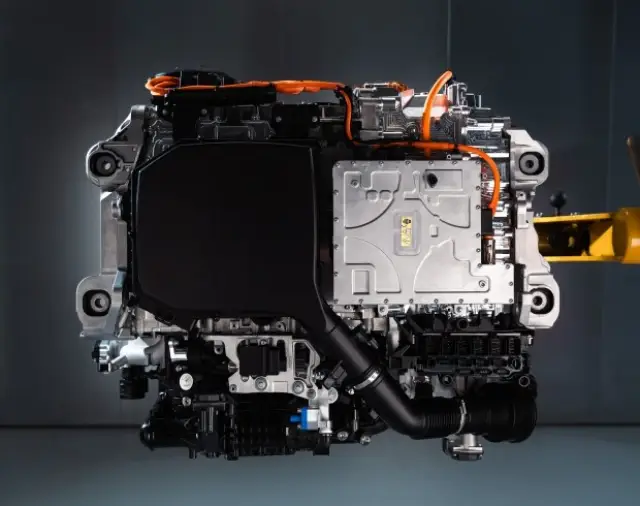

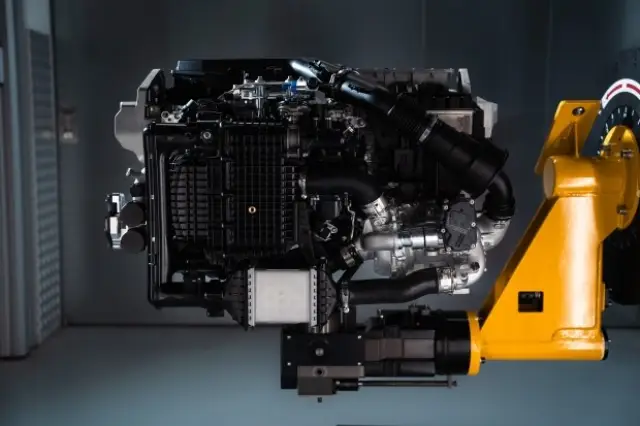

The new system is about a quarter more compact than previous generations. This not only makes it easier to integrate into different models, but also significantly improves efficiency. The increased power and reduced energy consumption guarantee a greater range compared to the second generation used in the BMW iX5 Hydrogen.

Production and innovation in Europe

The prototypes and their tests are being carried out in Munich. The series production of the fuel cells will be at the Steyr plant, which is currently undergoing a major modernization.

The Landsgut plant will specialize in the production of key components, including the unique "BMW Energy Master" power module. It is responsible for the distribution of energy and the integration of data from the battery.

With this move, BMW is strengthening its position as a technology leader, able to offer a variety of drives - electric, gasoline, diesel and hydrogen - depending on the needs of the market and customers.