Many big players in the emerging humanoid robot market are making bold sales forecasts, but the reality is that in their current form, these “human substitutes“ are not yet capable of finding widespread practical application. They still have many obstacles to overcome on the way to their popularity.

What we should not fear, as IEEE Spectrum explains, is a shortage of components to produce the necessary number of humanoid robots in the near future. In 2023, approximately 500,000 industrial robots were installed worldwide. If we assume that one humanoid robot is comparable in terms of the required components to four industrial manipulators, then the existing supply chain capabilities more than cover the most optimistic forecasts for the growth rate of the humanoid robot market. According to estimates by the same Bank of America, for example, by the end of the current year this market will be limited to 18,000 robots. Accordingly, it is unlikely to increase significantly next year, although Tesla plans to release about 50,000 Optimus robots next year.

Lack of demand and reliability

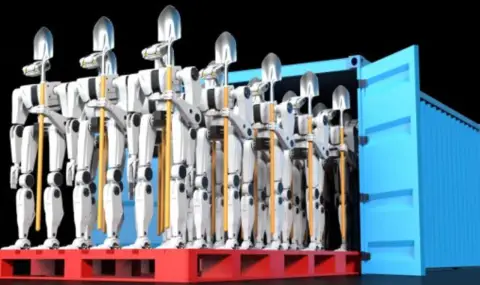

A much bigger problem, according to Meloni Wise, former product director at Agility Robotics, is the lack of sufficient demand for such products. It is unlikely that any potential buyer has yet figured out how to use several thousand humanoid robots in one enterprise. It is more profitable for robot suppliers to serve single orders from large customers than to cover the many needs of small ones. One scenario that suggests creating sufficient demand for large batches of humanoid robots is to specialize each group in a small set of operations - say, no more than ten. Most likely, the spread of humanoid robots in production in the coming years will be carried out precisely on this principle.

At the same time, there is no certainty that progress in the field of artificial intelligence systems will be able to proportionally increase sales of humanoid robots. The current level of development of artificial intelligence systems does not yet allow for a quick transfer of success to the humanoid robot market.

Like electric vehicles, modern robots have problems with battery life. For example, the Agility Digit model, which can carry loads of up to 16 kg, is equipped with a rather heavy battery pack, which allows it to work continuously for 90 minutes, and then charge for 9 minutes. Most likely, in practice, the periods of operation of such a robot before the next recharge will last no more than 30 minutes. When planning the robot's work schedule, it is necessary to include an “emergency reserve“ of 60 minutes, which will be needed either for emergency recharging or to eliminate possible technical problems. If this reserve is not taken into account, it is very likely that the robot will run out of power during operation and will have to be recharged manually. When about a hundred such robots weighing more than 100 kg each are working in the enterprise, few of the staff will want to encounter such problems.

For many customers of robot manufacturers, even short interruptions can lead to serious losses, so special requirements are imposed on the reliability of humanoid robots. Since the use of such robots in production will involve a wide variety of operations and working conditions, it is extremely difficult to ensure the necessary reliability of the complex as a whole.